Hi all,

I am referring to this thread:

I have added two M8 washers (got from ebay) to each of the two screws on the actuator between the turbo housing and the actuator.

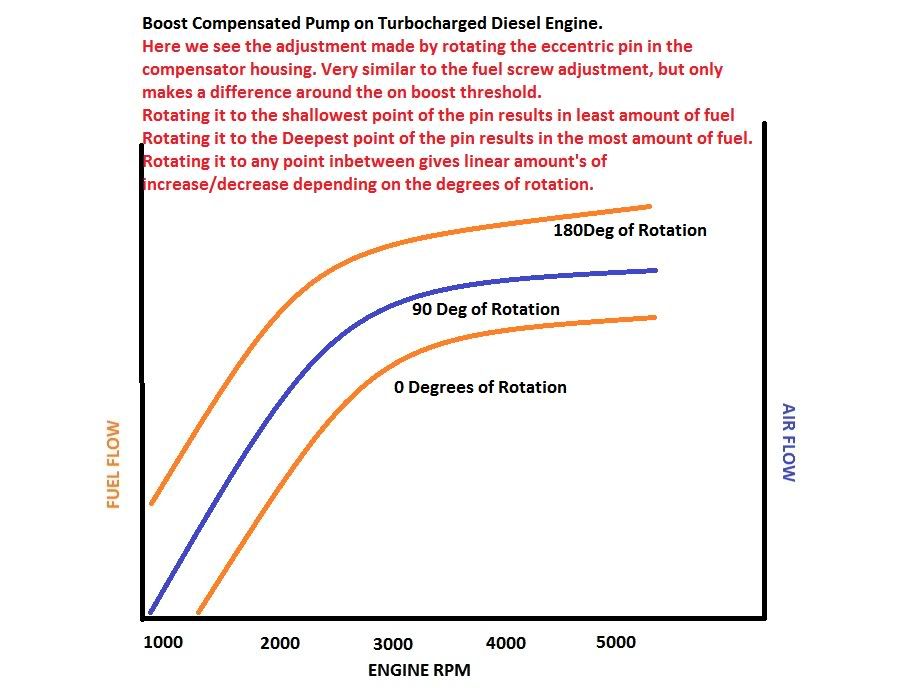

And the I was trying to do the diaphragm on the top of the pump, but it looks like the diaphragm has already to been turned 90 degrees.

As shown in the picture here:

Therefore I leave the diaphragm untouched as it is.

Then I had a good wash of the intercooler using petrol until the petrol becomes reasonably clean.

Didn't feel too much power increase though.

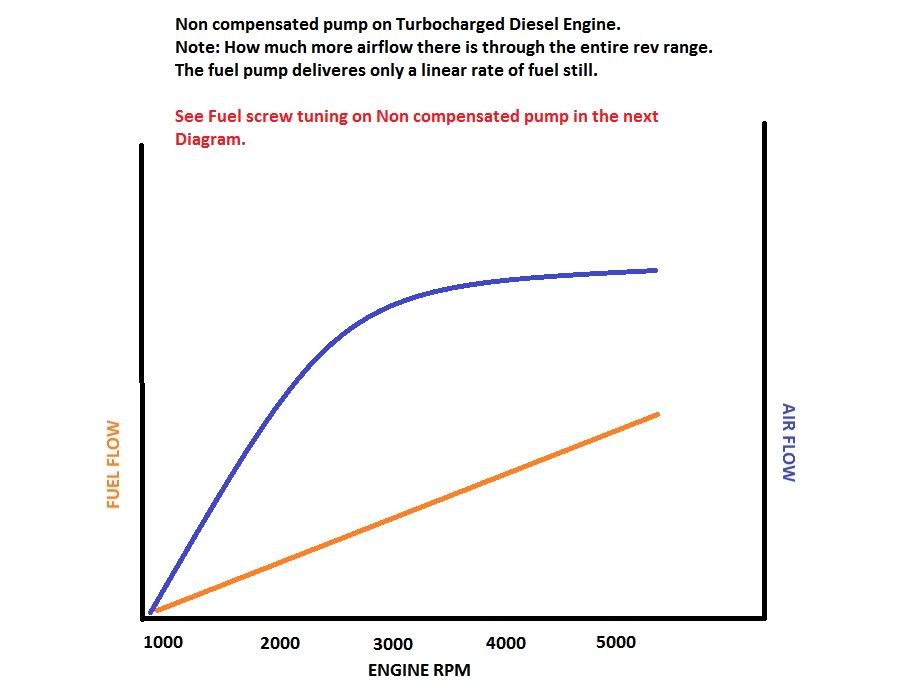

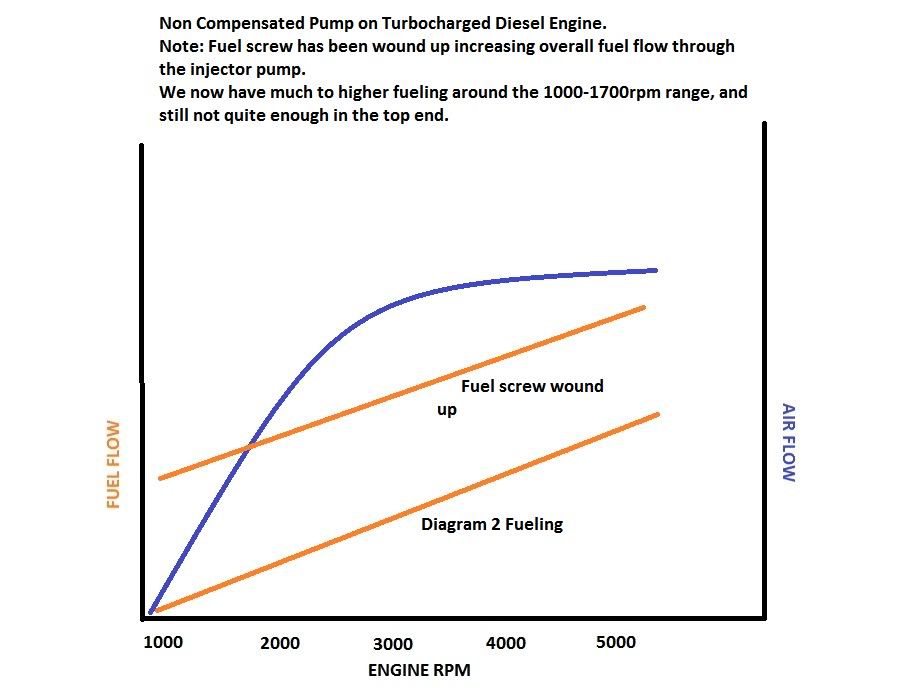

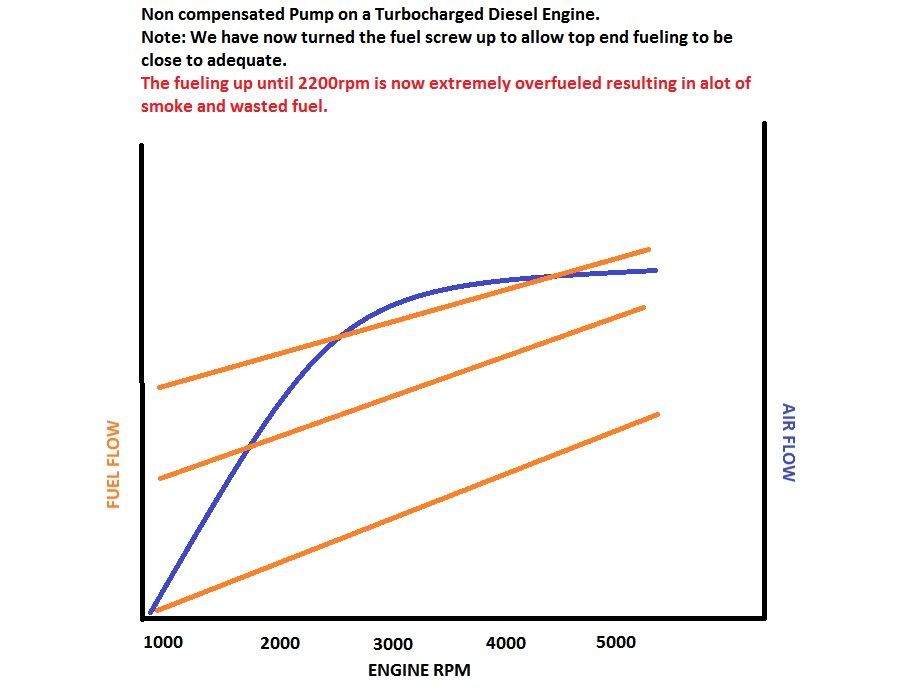

And it still blows a lot of black smoke at above 3000rpm.

Any idea to get rid of the smoke? Maybe I should tune the full power adjustment screw at the back of the pump?

I am referring to this thread:

I have added two M8 washers (got from ebay) to each of the two screws on the actuator between the turbo housing and the actuator.

And the I was trying to do the diaphragm on the top of the pump, but it looks like the diaphragm has already to been turned 90 degrees.

As shown in the picture here:

Therefore I leave the diaphragm untouched as it is.

Then I had a good wash of the intercooler using petrol until the petrol becomes reasonably clean.

Didn't feel too much power increase though.

And it still blows a lot of black smoke at above 3000rpm.

Any idea to get rid of the smoke? Maybe I should tune the full power adjustment screw at the back of the pump?

)

)

!! And yep she does use about 13l around town.

!! And yep she does use about 13l around town.

![Drive[1]](smilies/0/0/5/4/3/6/images/smilies/drive[1].gif)

Comment