Why is this always suggested over just going to the batteries negative terminal? say with spotlights & cable runs for fridges.

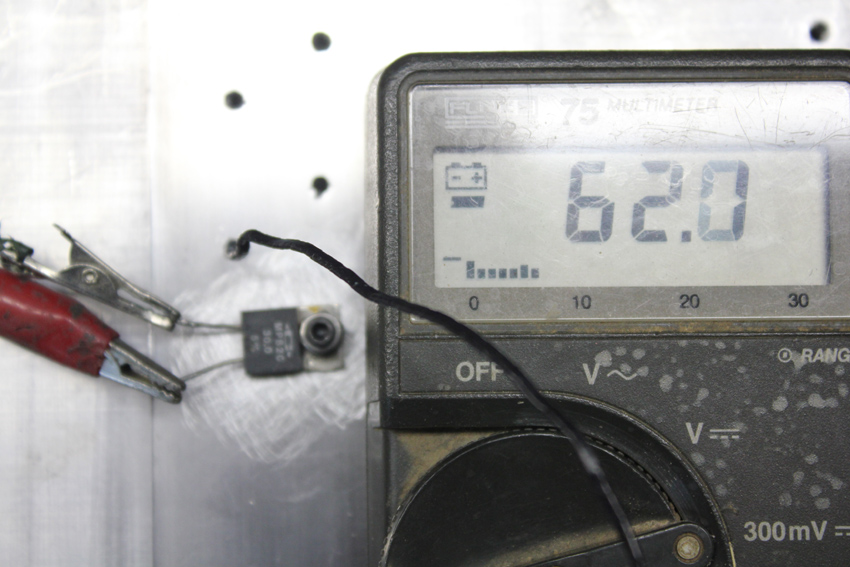

All parts of the vehicle exposed body have paint & are not bare metal, so there must be some significant resistance from the layer of paint. My bonnet pressure switch did not work while touching the metal frame, only in a pre existing hole where some of the paint was not present i think.

In my bonnet the main ground site looks to be attached to a worn area with no paint. or maybe an area that is rustless steel?

maybe I'm wrong about the paint? please correct me if so.

thanks

All parts of the vehicle exposed body have paint & are not bare metal, so there must be some significant resistance from the layer of paint. My bonnet pressure switch did not work while touching the metal frame, only in a pre existing hole where some of the paint was not present i think.

In my bonnet the main ground site looks to be attached to a worn area with no paint. or maybe an area that is rustless steel?

maybe I'm wrong about the paint? please correct me if so.

thanks

![Beer[1]](https://www.pajeroforum.com.au/core/smilies/0/0/5/4/3/6/images/smilies/beer[1].gif)

![Disappointed[1]](https://www.pajeroforum.com.au/core/smilies/0/0/5/4/3/6/images/smilies/disappointed[1].gif)

Comment